| |

|

| |

| |

[

] |

| |

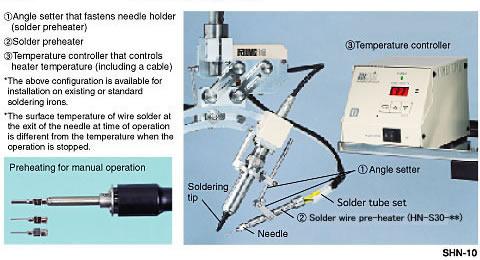

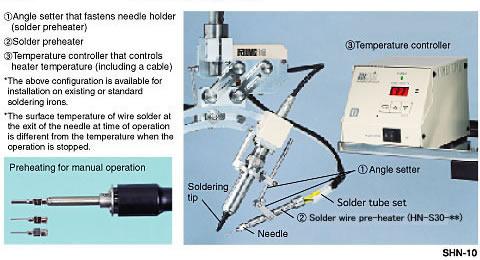

Solder Wire Pre-heater [SHN-10]

|

| Preheating of wire solder itself will help reduce spattering of flux and solder balls. |

|

| FEATURES |

- When wire solder is supplied to the soldering tip heated to high temperature, the flux inside may heat up and explode due to abrupt heating. This heat shock is one of the causes of spattering of flux or solder balls. Our product SHN-10 has the effect of reducing this shock.

- It is reported that preheating of solder has an increasing effect of activation on flux and improves good break-off and even spreadability of solder, and besides work time can also be reduced. This has the same effect as preheating of reflow ovens.

- The SHN-10 keeps the temperature at the soldering iron from lowering during soldering operation, and stabilizes the temperature. Through this stabilization of the temperature, it will be possible to set the temperature at the soldering iron to a minimum.

- By keeping the temperature at the soldering iron low, development of flux carbide can be restrained. Also, it has a restraining effect on wear of the soldering tip caused by thermal oxidation.

|

| APPLICATIONS |

- lead-free solder

- high-temperature solder

- multi-layer through hole boards

- ceramic boards

|

- flexible cables

- crimping portion of leads

- lead frames

- liquid crystal TAB

|

|

|

|

|

|

|

|

|

|